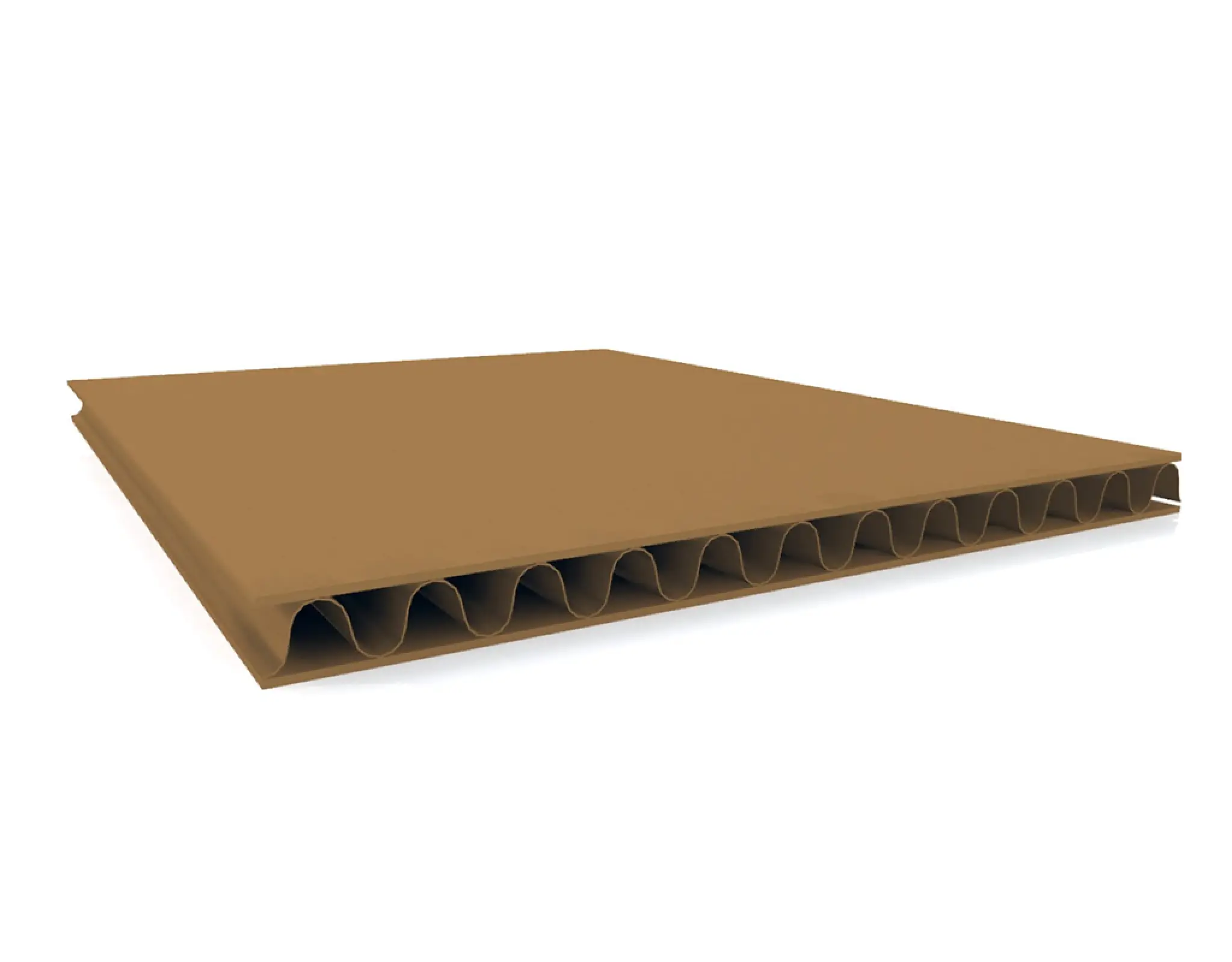

Single Face

Single Face fluted grades consist of one fluting medium glued to a single linerboard. Single Face Flute, is a popular type of corrugated cardboard used in packaging and shipping materials. This unique flute consists of one layer of fluting, which is the wavy or rippled part of the cardboard, sandwiched between two flat sheets of paper. This construction creates a strong and lightweight material that is perfect for protecting fragile items during transportation.

The single-face flute is commonly used for smaller and lighter products, such as electronics, cosmetics, and food items. Its versatile nature also allows for easy customization and printing, making it a top choice for businesses looking to brand their packaging. With its cost-effective and eco-friendly properties, it's no wonder that the use of single face flute continues to grow.

Single Wall

Single Wall fluted grades have one fluting medium sandwiched between two linerboards. Single wall flute is a type of corrugated cardboard that is becoming increasingly popular for packaging and shipping purposes. The flute, or wavy layer between the two flat cardboard layers, is what gives this material its strength and durability. Compared to double wall flute, single wall flute is thinner and more lightweight, making it a cost-effective option for businesses looking to reduce shipping costs.

However, this does not compromise its strength as it can still withstand heavy loads and provide adequate protection for delicate items. In addition to its practical uses, single wall flute is also environmentally friendly as it is made from recycled materials. Overall, single wall flute offers a versatile and efficient solution for packaging and shipping needs.

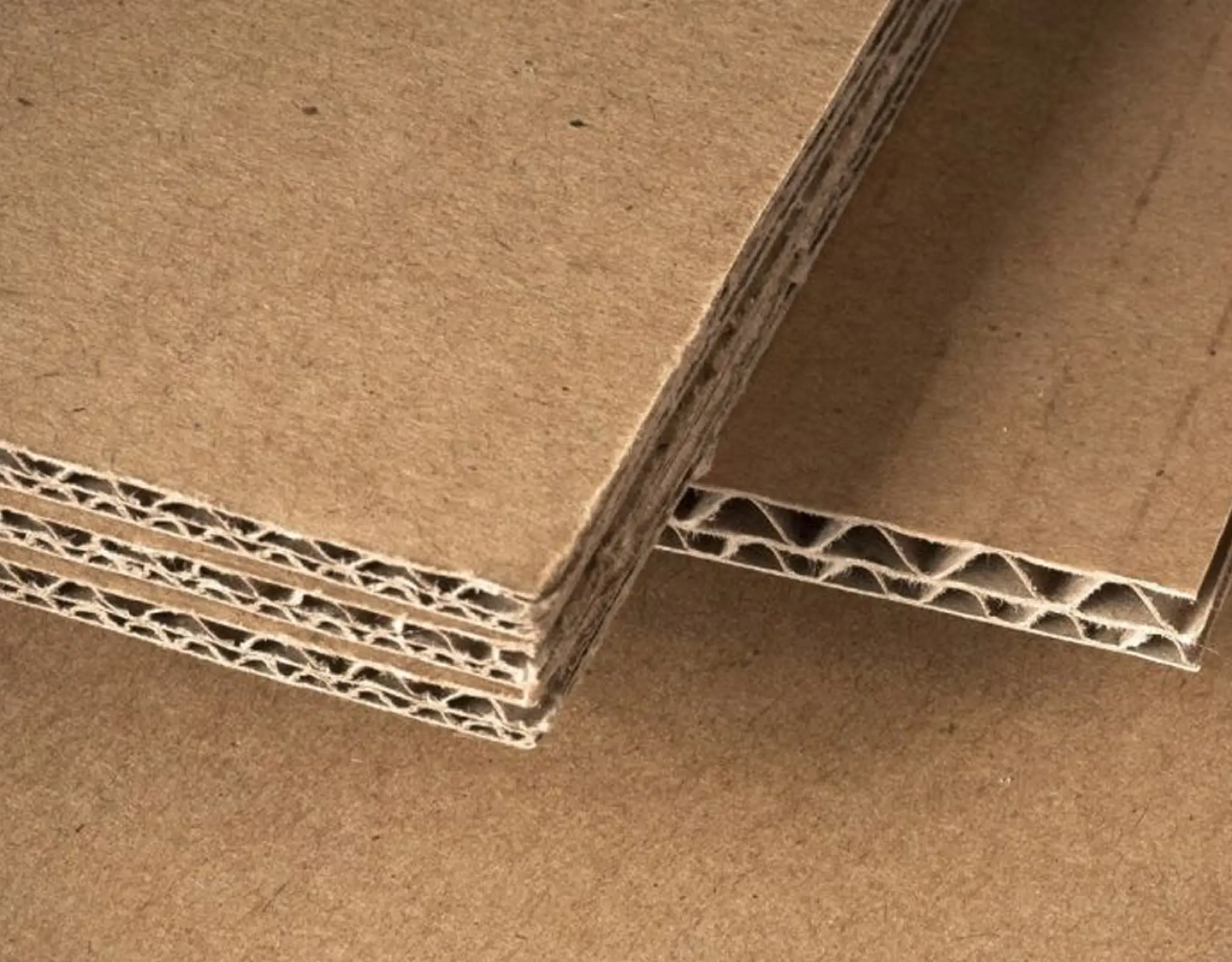

Double Wall

Double Wall fluted grades feature two fluting mediums and three linerboards. Double wall fluted grades are becoming increasingly popular in the packaging industry due to their versatility and strength. These grades are created by combining two layers of corrugated paper with a fluted inner layer, providing superior protection for delicate items during transportation. The double wall construction also offers added durability, making it a great option for heavy or bulky products. Additionally, these grades have excellent printability and can be customized with various coatings or finishes to enhance the visual appeal of the packaging. With the growing demand for sustainable packaging solutions, double wall fluted grades are also an eco-friendly choice as they are made from recyclable materials. Whether for shipping, storage, or display purposes, these grades provide an ideal solution for all types of packaging needs.

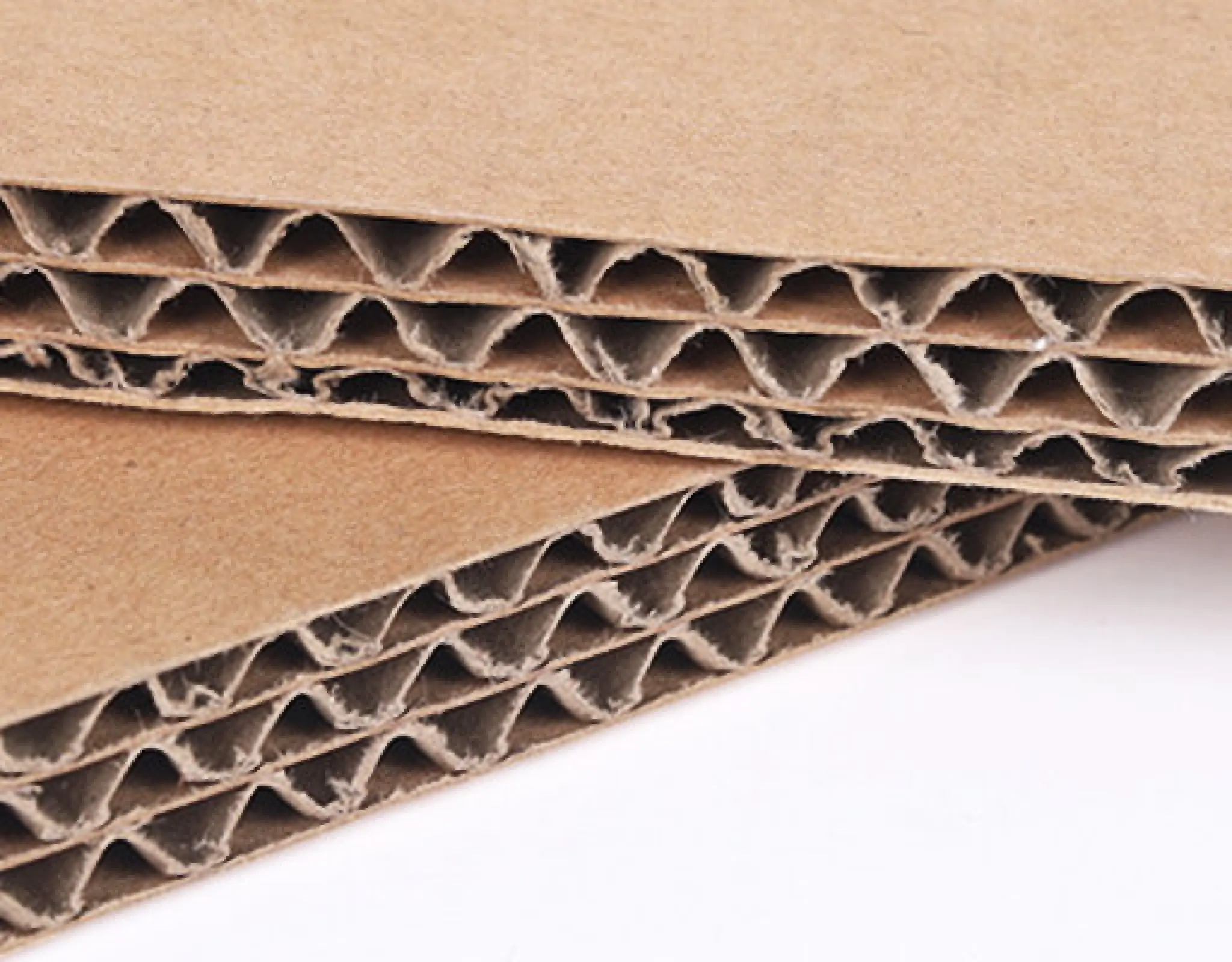

Triple Wall

Triple Wall fluted grades have three fluting mediums and four linerboards. Triple wall fluted grades refer to a type of corrugated cardboard with three layers of fluting in between four layers of linerboard. This results in a strong and sturdy packaging material that is suitable for heavy-duty applications. The three layers of fluting provides added strength and rigidity, making it ideal for shipping and storing bulky items. The grades of triple wall fluted cardboard can vary, with some offering higher compression strength and others designed for moisture resistance. Overall, these grades offer superior protection and durability, making them a popular choice for packaging solutions in various industries. Additionally, the triple wall construction also provides insulation, making it a suitable option for temperature-sensitive products.

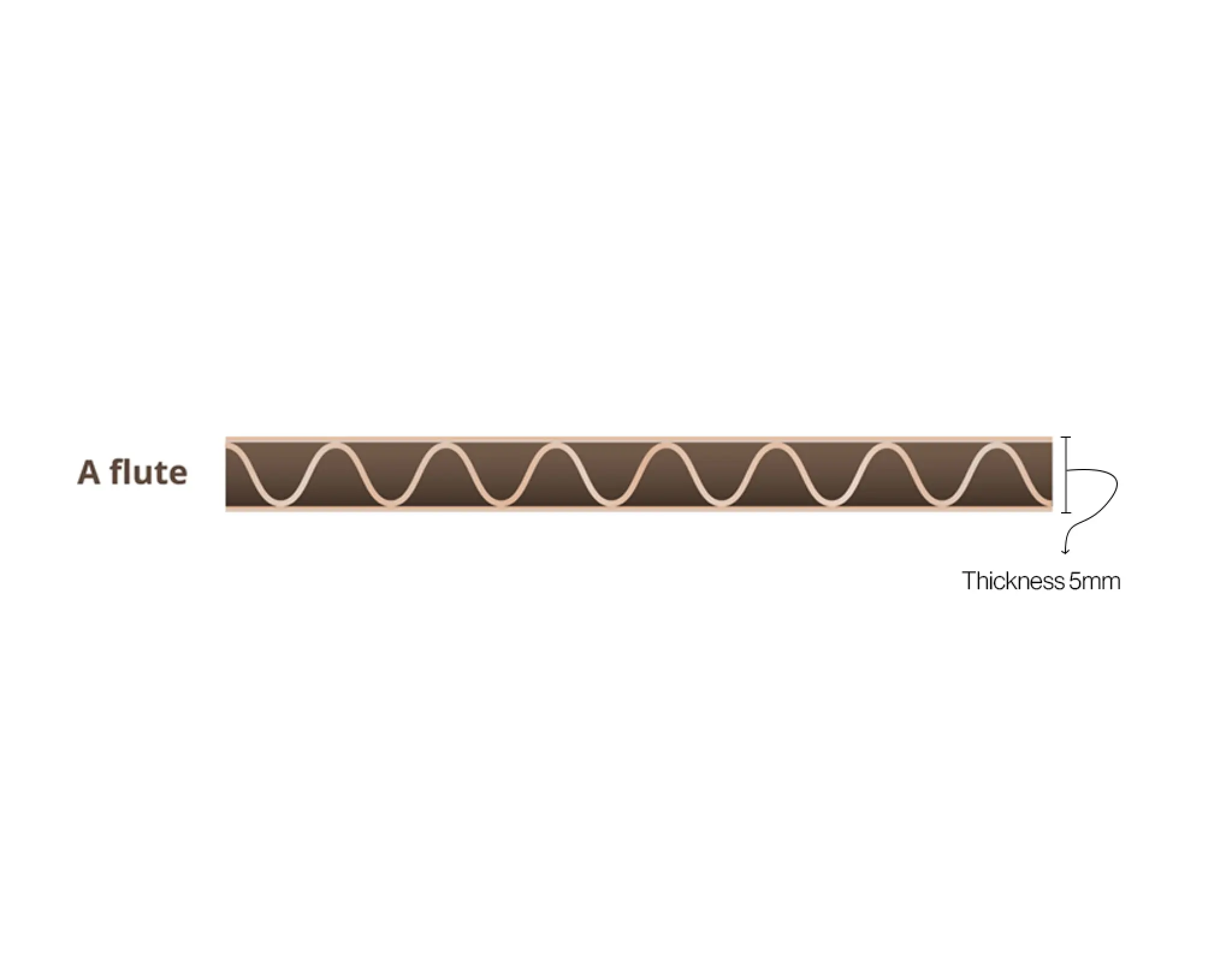

A-Flute

A-Flute is the largest and thickest among the common flute types. It offers excellent cushioning properties and vertical compression strength, making it ideal for packaging heavy or fragile items. A-Flute has a distinctive thick and sturdy feel, with visible fluting on the surface of the corrugated board. Its structure provides superior stacking strength and resistance to crushing, ensuring the protection of the packaged products during handling and transportation.

A-Flute's robustness and cushioning properties make it a popular choice for packaging heavy or delicate items such as furniture, automotive parts, and large appliances. Its thick walls and large flute size offer exceptional protection against impacts, vibrations, and compression forces during shipping and storage. A-Flute is also commonly used for creating pallet boxes, industrial bulk containers, and heavy-duty shipping boxes. The flute's ability to withstand high stacking loads makes it suitable for storing and transporting products in warehouses or distribution centers. Additionally, A-Flute's thickness allows for easy printing and lamination, enabling the creation of attractive and informative packaging designs for retail displays or point-of-purchase applications.

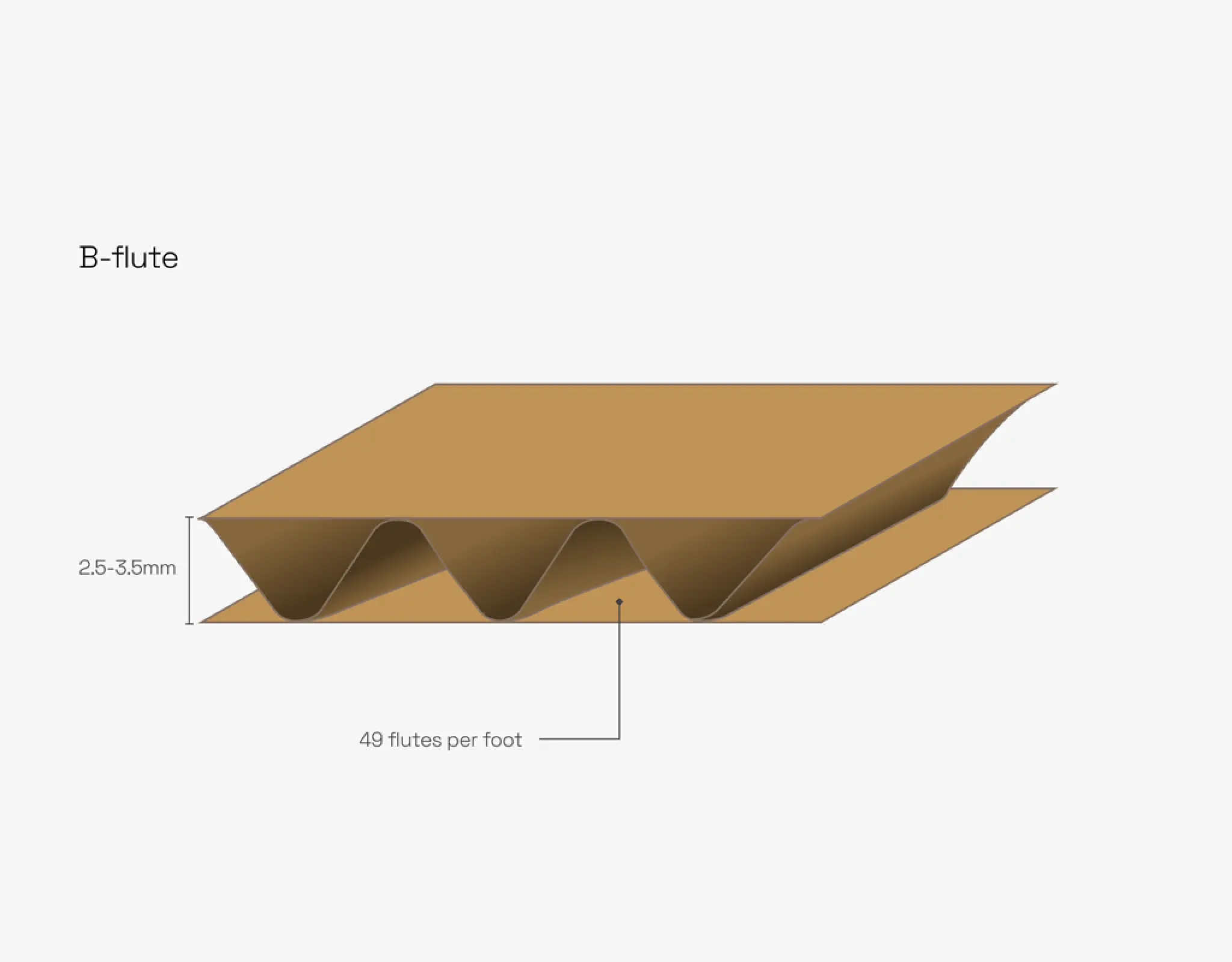

B-Flute

B-Flute is slightly smaller than A-Flute. This flute strikes a balance between strength and printability, offering good cushioning properties and a smoother surface compared to A-Flute. B-Flute's smaller flute size results in a higher number of flutes per unit length, providing increased rigidity and better flat crush resistance.

B-Flute's smaller flute size provides good cushioning and protection for medium-weight products, such as canned goods, cosmetics, and small electronics. B-Flute's smoother surface is well-suited for high-quality printing and graphics, making it ideal for retail packaging, shelf displays, and marketing materials. The flute's compact structure also enables more efficient storage and transportation, as more packages can be stacked in a given space compared to larger flute sizes. Additionally, B-Flute is commonly used for inner packaging components, such as dividers, partitions, and pads, providing additional protection and organization within larger shipping containers.

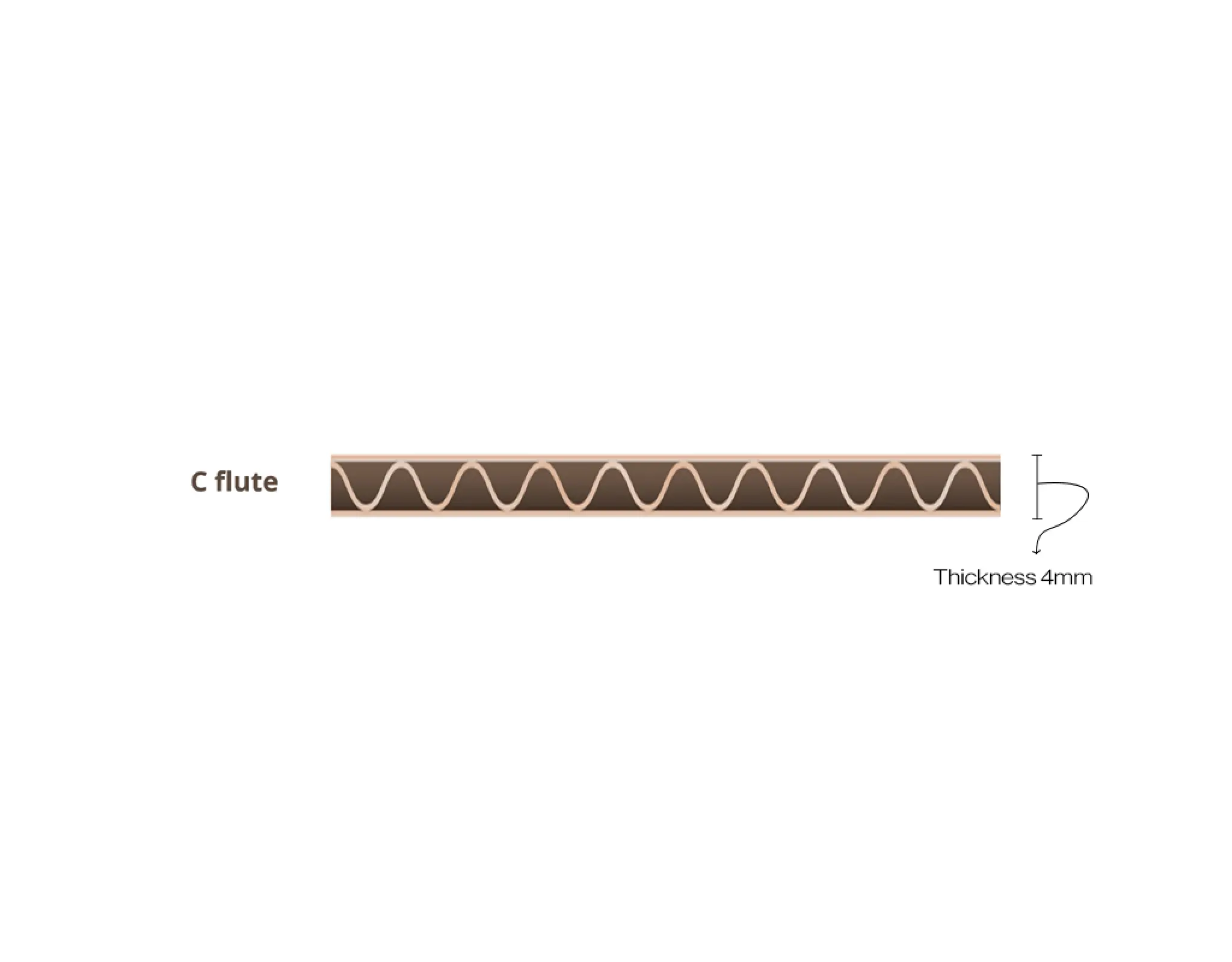

C-Flute

C-Flute is the most commonly used flute size in the packaging industry. C-Flute offers an optimal balance between strength, cushioning, and printability. C-Flute has a moderate flute height, providing good stacking strength and crush resistance while maintaining a relatively smooth surface for printing.

C-Flute's versatility and balanced properties make it suitable for a wide variety of packaging applications. Its moderate flute size provides adequate cushioning and protection for products of various weights and sizes, such as food items, beverages, toys, and household goods. C-Flute's good printability enables attractive and informative packaging designs, enhancing the product's shelf appeal and brand recognition. The flute's stacking strength allows for stable and secure palletization, facilitating efficient transportation and storage. C-Flute is also commonly used for creating secondary packaging, such as outer boxes, shipping containers, and retail-ready packaging (RRP) solutions. Its cost-effectiveness and wide availability make it a popular choice for businesses looking to optimize their packaging while maintaining quality and performance.

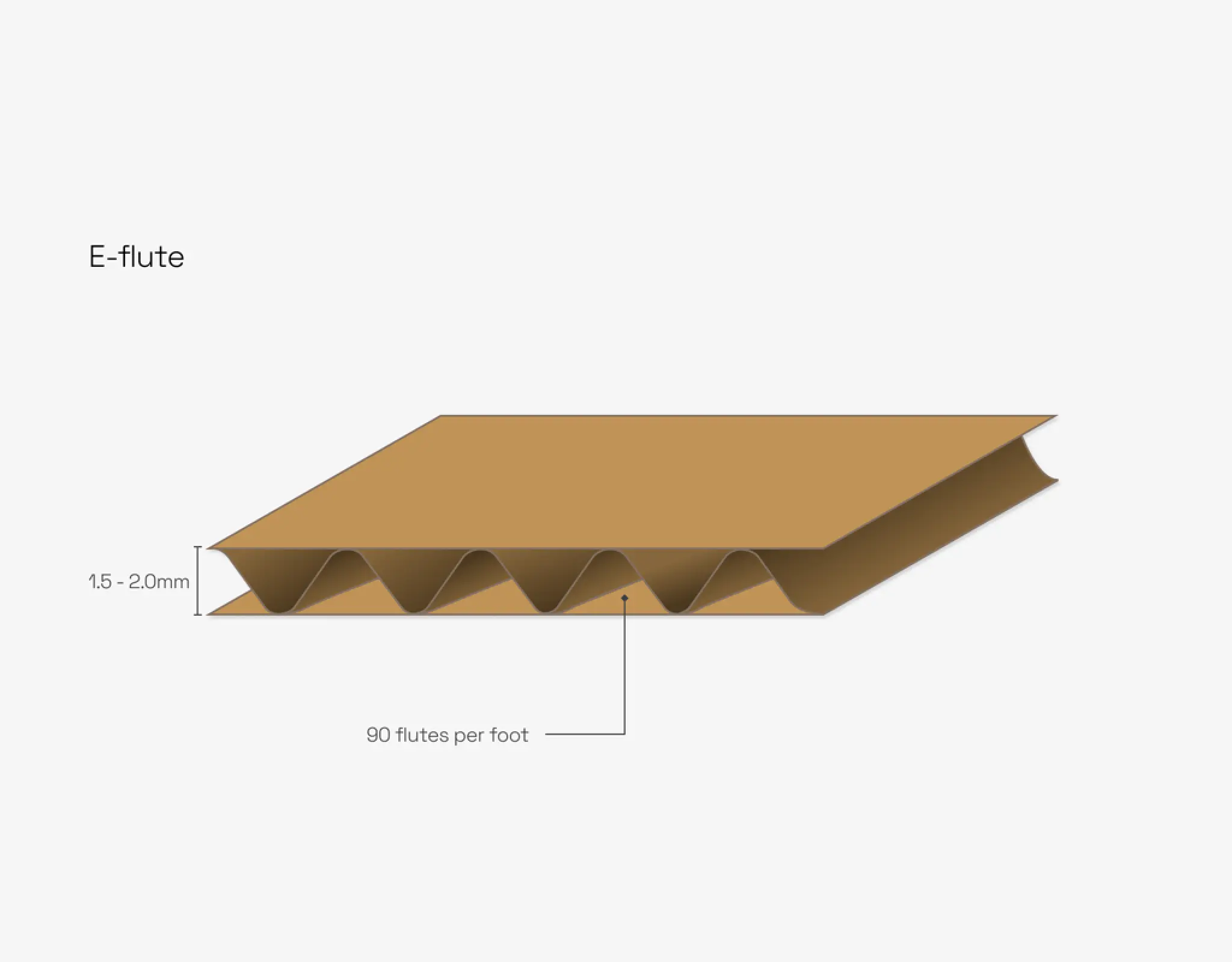

E-Flute

E-Flute is the smallest and thinnest among the common flute types. This flute size offers excellent printability and a smooth, almost flat surface, making it ideal for high-quality graphics and intricate designs. E-Flute's thin profile results in a lightweight and compact packaging solution, reducing shipping costs and storage space requirements. Despite its thinness, E-Flute still provides a level of protection and rigidity suitable for lightweight and less fragile products.

E-Flute's exceptional printability and smooth surface make it a preferred choice for packaging applications that prioritize visual appeal and brand presentation. Its thin profile allows for the creation of sleek and attractive packaging designs, such as cosmetic boxes, pharmaceutical cartons, and high-end consumer goods packaging. E-Flute's lightweight nature reduces shipping costs and minimizes environmental impact, as more packages can be transported in a single shipment. This flute size is also commonly used for inner packaging components, such as trays, inserts, and protective layers, providing additional support and organization within the main packaging. E-Flute's compact structure enables efficient storage and display, making it suitable for retail environments with limited shelf space.